LT anniversary blog

LT future talents

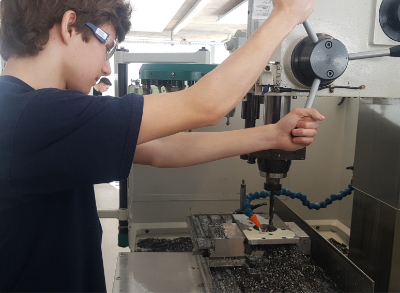

Marco Fankhauser is standing at a CNC-controlled lathing and milling machine, placing raw material into the automatic bar loader. The movements needed to operate and load the machine come easily to him. Marco is in his third year as an apprentice, and he operates difficult CNC machines every day. Just like his colleagues, he is very enthusiastic about working with high-quality materials which LT uses to produce parts.

Ask apprentices Marco Fankhauser and Bastian Zeiter why they are doing their training at LT and you will hear very personal reasons for why they made their decision. “From the very first day of training, we have felt every day that LT is a family company. Our colleagues give us a lot of their time and it’s a real pleasure to come here each and every day,” says Bastian.

“I really enjoy the combination of precision and technology. That’s why I want to be a polymechanic,” adds Marco. He is not a man of many words, preferring to focus on the lathing machine he is using at the moment. With a critical and yet affectionate look, he checks the lathed parts he has just finished. They will be put to use by customers in just a few days.

Exchange of experiences as a core competency

LT has three apprentices at the moment. Sandro Zürcher, Marco Fankhauser and Bastian Zeiter are in their first, third and fourth years respectively as apprentices and are training to be polymechanics. At the moment, the group also includes Joél Brechbühl. He is an exchange learner and originally comes from an LT partner. He is spending three months at LT in Trub, as exchange is important – not only within the company among apprentices and employees.

By providing training at the company, LT is countering a problem that is pervasive throughout Switzerland: it is difficult to find well-trained experts for production. For this reason, LT will continue to offer apprenticeships in the coming years. This is not only good for LT, it also strengthens the Upper Emmental as a business location.

From basic training to CNC expert

Michael Steiner has been responsible for training apprentices at LT for four years, and he provides them with support on a daily basis. “The training is relatively demanding, but working with the youngsters is fun.”

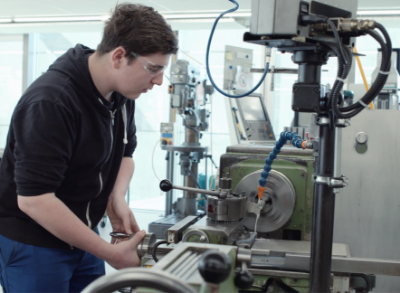

Apprentices at LT get to know all areas of production and become familiar with all of the equipment. They start basic training by working with the conventional lathe. “This provides us with a sense of how the materials behave,” says Joél. From there, the equipment becomes increasingly complex and the apprentices take on more and more responsibility.

For Thomas Beer, the second trainer at LT, it is clear why things never get boring during the training at LT. “We constantly produce different parts here. The settings on the machines have to be adjusted for each one and apprentices are able to expand their knowledge on a daily basis.”

Many apprentices remain at LT following their apprenticeship. This, too, is part of the recipe for success in Trub: not only train the experts, but also keep them in the Emmental.

30 apprentices in nearly 40 years

LT has been training apprentices since 1981. Previously, the company trained agricultural equipment mechanics, now it trains polymechanics and production mechanics. The career information portal berufsberatung.ch summarises the polymechanic profession in two sentences: “Polymechanics produce tools, machine components and production equipment. They program and operate machines, monitor production, put machines into operation and maintain them.” Most of the apprentices who find their passion and vocation in this profession at LT are young men, however, women are of course also trained at LT. Usually they opt for a commercial apprenticeship.

<< back to the overview