LT anniversary blog

Simon Lehmann: driver of cultural change at LT

Simon Lehmann took over management of the family business from his father Bruno in 2012. The two created a masterpiece of succession planning: At age 56, Bruno Lehmann stepped back from operational management of the company, putting his full faith in Simon. And Simon managed to go his own way under difficult circumstances. He faced completely different challenges compared to his father and grandfather. He needed an ERP system for Lehmann Trub (LT) that would stand the test of time; he had to make a major move towards digitalization in sales and set up an online shop; and he had to maintain the company’s production position despite increased price competition. In short, Simon is navigating LT through the entrepreneurial cultural change that is taking place at the start of the 21st century.

A family business with family people at the top

The one thing that links the entrepreneurs of the Lehmann family across all generations is their sense of family. Simon Lehmann is a family man as well. Following his training as a machine mechanic at the Bern Technical College, where he received his vocational baccalaureate, he gained a bachelor’s degree and continued his studies at the University for Economics and Administration (HWV) and in London. He completed his studies in 2006 and then gained experience at Stadler Rail and Leica Geosystems for several years before joining the family company in Trub. He had now acquired specialized technical knowledge as well as some initial international experience – and met the woman of his dreams in London. Eriko, originally from Japan, followed Simon to the Emmental. She is the love of Simon’s life: “Eriko is the best thing that’s ever happened to me.” He has two children with her and her full support for his work at LT – at home in the Emmental and in Bogor, not far from the Indonesian capital of Jakarta, where he has been setting up PT Lehmann Technology Asia (LTA), a partner company of LT, since 2015.

LT moves down the path towards the digital future

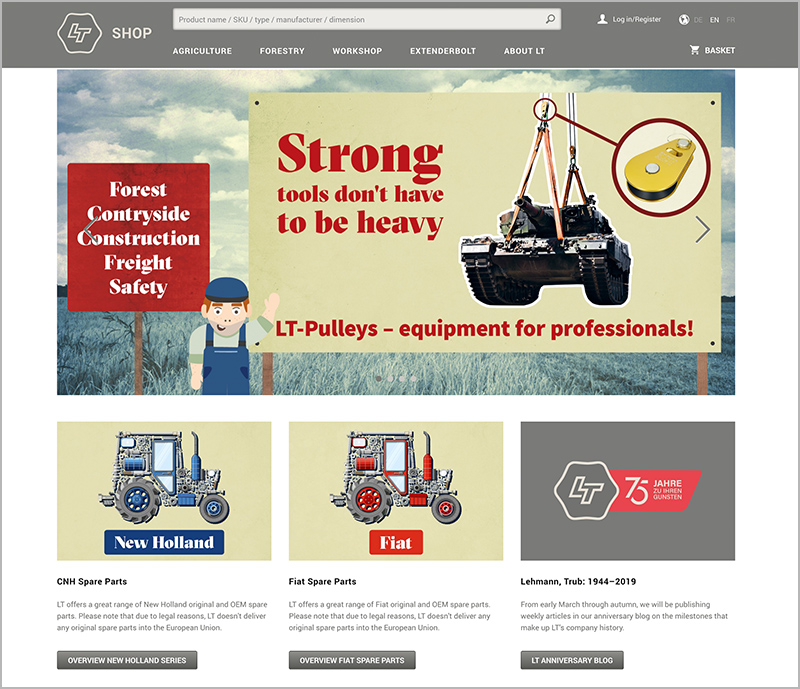

Major changes were underway when Simon Lehmann took over the family business. Optimization of business processes and digitalization were the order of the day. Simon opted for an ERP system from Sage and worked with an e-commerce specialist from Germany to develop an online shop for the company, which already had more than 20,000 products when it went live in 2014. By 2019, the company’s anniversary, 30,000 products are available online, nearly all of which have both a precise product description and an image.

The online shop helps to keep LT competitive on the retail market

What makes shopping at www.lt-shop.ch so special is not only its enormous range of products and the high availability of these items, but also the specialized staff who manage the LT shop. These employees are agricultural machinery mechanics themselves and know the products inside and out. This ensures that customers receive excellent support from LT. Another ingredient that adds to the success of LT’s e-commerce platform: speed! Every order placed by 5.15 p.m. is delivered the next day. Orders at LT are picked up daily in Trub by the postal service. Simon Lehmann put himself in the position of his customers and listened to them. A customer who needs a spare part generally wants and needs it right away. LT makes sure this happens.

Expansion of production expertise

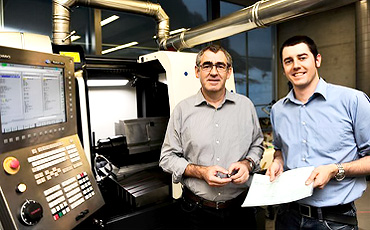

Simon Lehmann received a call one day in 2014. Alfred Prinz, the owner of HiproCNC, made him an offer: “Simon, I want to sell you my company.” The two had known each other for years, and Alfred Prinz could not imagine anyone else buying his company, as he had had a long-term partnership with the Lehmann family that went beyond a business relationship. Simon did not wait long, and within just a few weeks, the contracts had been signed and HiproCNC moved from Zollbrück to Trub. HiproCNC specializes in complex turned and milled parts for the machinery industry and has made a good name for itself. Simon Lehmann has a lot of respect for Alfred Prinz: “He placed his confidence in me and entrusted me with his company – his life’s work.”

Establishment of sister company LTA in Indonesia

Simon Lehmann took another major manufacturing step just one year later. His solution for surviving the hard-fought price war that had erupted since the abolition of the EUR/CHF minimum exchange rate in January 2015 was to establish LTA in Bogor, Indonesia, around 60 kilometres south of Jakarta. The sister company of LT commenced operations in the areas of CNC manufacturing and component assembly in October 2015. As a result, Simon Lehmann has provided LT’s manufacturing customers with new options: Swiss quality at Asian terms, ensured through the collaboration with their trusted Swiss partner, LT. At first, however, the Indonesian location resulted in headwinds for Simon Lehmann. Many view LTA as a traditional Swiss company leaving Switzerland for Southeast Asia. Simon Lehmann counters by saying: “This is the only way we can remain competitive. Because part of our production processes takes place in Indonesia, new markets are becoming accessible, such as Asia itself and Australia. The production of very complex parts and the development of new products will continue to take place in Trub.”

The appearance of LT on the global market

The pulley is a universal tool that LT developed in-house in Trub and now offers globally.

<< back to the overview